Recyclability in Australia refers to the ability of materials to be collected, processed, and reused or repurposed into new products or materials. This typically involves sorting, cleaning, and processing recyclable materials such as paper, plastic, glass, and metal so they can be reintroduced into the manufacturing process. Recyclability is governed by various regulations and standards set by federal, state, and local governments, as well as industry bodies.

‘Greenwashing’ in the Market

As businesses push to provide an environmentally-friendly messaging to consumers, greenwashing starts to become more rampant. Greenwashing refers to the deceptive or misleading claims made by companies regarding the environmental benefits of their products or practices. The Australian Competition and Consumer Commission (ACCC) has been actively involved in combating greenwashing by enforcing consumer laws, providing guidelines and recommendations, monitoring the marketplace for potentially misleading environmental claims and educating consumers with resources about greenwashing and encouraging them to be vigilant when interpreting environmental claims made by businesses. By providing packaging products with sustainable integrity, your business can provide consumers with products that adheres to government guidelines.

REDCycle Australia & Next Steps

Australia generates over 70 billion pieces of soft plastic annually, with much of it ending up in landfills or polluting streets, rivers, and oceans. Following the collapse of Australia’s largest soft plastic recycling program, REDcycle, in late 2022, a new initiative is emerging, albeit on a smaller scale. The trial, currently underway in 12 Melbourne supermarkets, aims to provide customers with an in-store option for recycling “scrunchable” food packaging.

APCO supports the supermarkets’ dialogue to develop a pathway forward to reinstate soft plastic collection solutions as soon as possible and consider the economics, pricing and governance model needed to support soft plastic recovery and recycling moving forward. The removal of the REDcycle is currently in transition until 2025.

Multi-Layer Pouches vs Mono Polymer Pouches

Pouches are well-known and great packaging options for food and pantry products. However, choosing the right one that supports your business’ goals can be daunting as multi-layer and mono-polymer pouches are two different types of packaging materials, each with its own end of life. Here’s a comparison between the two:

- Mono-polymer Pouch

- Multi-Layer Pouch

- Multi-layer pouches:

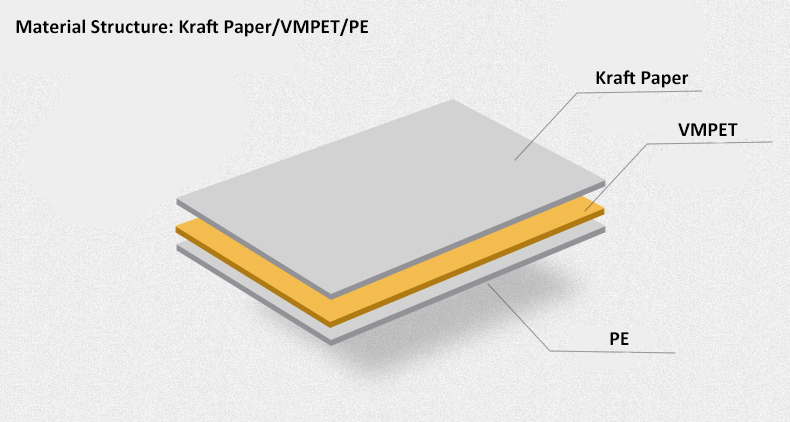

- Multi-layer pouches are constructed using several layers of different materials laminated together to provide specific properties such as barrier protection, strength, flexibility, and printability.

- Common materials used in multi-layer pouches include combinations of plastics like polyethylene (PE), polypropylene (PP), polyester (PET), aluminium foil and paper which they offer excellent barrier properties against moisture, oxygen, light, and odors.

- However, multi-layer pouches can be challenging to recycle due to the complexity of separating and processing the different layers of materials.

- Mono-polymer pouches:

-

-

- Mono-polymer materials consist of a single type of polymer, such as polyethylene (PE) or polypropylene (PP), without any additional layers or laminations which are designed to be more easily recyclable compared to multi-layer structures.

- Often used for applications where recyclability is a priority or where specific properties of the polymer, such as clarity or stiffness, are desired.

- Used for various packaging formats including films, bags, bottles, and containers.

- Function coatings can be applied to mono-polymer materials to enhance their barrier properties, ensuring the freshness and quality of the packaged food products.

-

Introducing Myerton Packaging’s Kerbside Recyclable Pouch

Myerton Packaging offers a range of innovative kerbside recyclable pouches designed to address the pressing issue of unnecessary plastic waste management. By prioritizing recyclability without compromising on functionality or performance, these pouches exemplify Myerton Packaging’s dedication to sustainable packaging solutions that meet the evolving needs of businesses and consumers alike.

Benefits of Roll ‘n’ Recycle® Kerbside Recyclable Pouches

- Provide an easy way of recycling to your customers: Myerton Packaging’s kerbside recyclable pouches are made with mono polymer containing over 95% PE/PP, eliminating aluminuim or plastic layers.

- Reduce your carbon footprints and transportation costs: Weighted around 10% less per pouch than conventional pouches, our kerbside recyclable pouches generate fewer carbon emissions in production and transportation and bring down transportation costs as well.

- Protect your products with high performance and present your branding with superior printing capabilities: Made with recyclable materials, our kerbside recyclable pouches provide excellent oxygen barrier with a transmission rate of (OTR) ≦5 (cm³/m².24hrs) and moisture barriers with a water transmission rate of (WTR) ≦10 (g/m².24hrs).

Explore our full range of food packaging here.