Yes, it is our company policy to present samples so that you can make sure it meets your requirements and avoid any mistakes. We do not make a profit margin from samples. The cost of the samples may vary depending on the product. If there is a quality issue or mistake, we will re-make it at no cost to you. However, if you want to change anything on the product, that may attract a second sample charge.

For sample requests, please Contact Us and advise us of your packaging needs.

What's the turn around time?

Our manufacturers are based overseas; we will organize shipment ASAP.

- We will use air freight for lightweight products, such as ribbons, labels, etc.; the turnaround time is 2-4 weeks.

- For heavy products and bulk orders, we will transport them by sea; the turnaround time is 8-12 weeks from the confirmed order or deposit receipted to deliver to you.

What's the minimum order quantity?

MOQ varies for different products.

- Premium Paper Bags: 2500pcs

- Takeaway paper bags: 5000pcs

- Labels/Stickers: 5000pcs

- Ribbons: 2000 yards (40 rolls)

- Corrugated boxes: 3000pcs

- Cardboard Boxes (folding cartons): 5000pcs

- Rigid boxes: 1000pcs

- Food grade boxes: 5000pcs

- Food pails: 50,000pcs

I can't find a particular product, what should I do?

You can try to search by its name in the search bar above; if a product you are looking for is unavailable on our website, please Contact Us and we will recommend a suitable alternative. If you are looking for a custom-made product, please contact us for a quote.

I have a quality concern /complaint about a product, how should I resolve this?

Within two business days after delivery, you can give us notice of any claim for damages on account of the condition, quality, or grade of the goods, specifying the basis of the claim in detail. Otherwise, failure to notify us under the conditions constitutes an irrevocable acceptance of the goods.

Why can't the printed colours be 100% the same as seen on my monitor?

The colour you see on the screen is RGB (Red, Green and Blue), the colour space for digital images. In contrast, CMYK (Cyan, Magenta, Yellow, Key/black) is what is produced in the digital printing process. The printing machine creates images by combining CMYK colours.

(RBG colours on the screen vs CMYK colours printed)

Why can't the colours be printed 100% the same for every print run?

- The colour and composition of the paper affect the printed colour

- Papers have different chemical compositions, additives, textures, finishes, etc., reacting differently with the inks and toners of digital and conventional presses.

How can we prepare print-ready files?

We will provide you with a dieline template and assist with working with your designers to ensure your design meets our artwork requirements for printing. For more comprehensive information, please see our artwork requirements.

What’s the differences between coated and uncoated papers?

Coated paper has a coating on them to improve brightness and smoothness. Whereas uncoated paper doesn’t have a coating to fill in between the fibres, it has a natural and rough texture. The coated paper doesn’t have to be considered glossy; it can be coated with glossy or matte finishes, whereas uncoated only has a matte finish.

Impact on the printing

The coated paper is “sealed”; it lets the ink settle on the surface, so the printings look deeper and more vibrant. Uncoated paper is more porous, absorbing more inks and making the printing dull and not as prominent.

Examples

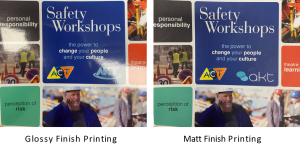

What’s the differences between a glossy and matte finish?

A glossy finish will come with a smooth and shiny appearance. It is also very colour vibrant. However, because of this, it will be reflective. Opt for a glossy finish if you want a shiny look.

Whereas a matte finish will offer a more neutral and natural look. It will give your packaging an overall softer and more luxurious look. It won’t be reflective as the glossy finish.

Examples