In today’s fiercely competitive business landscape, packaging serves as more than just a vessel for products—it’s a canvas for creativity, storytelling, and a powerful tool for shaping brand identity. In this article, we explore the different types of packaging embellishments and their specific use to guide your next packaging redesign.

Let’s Explore: Paper Bag and Box Embellishments

Two of the most common packaging in the custom space are paper bags and boxes. Not only do they cater to retail shops but they also expand to events and gifting industries – making them the most viable choice for adding personalised embellishments. Here are the most common packaging embellishments you can apply while understanding the benefit:

Hot Foil

If premium and luxurious is what you describe your brand, this embellishment is for you! Renowned for its elegance, it is great for conveying a message made from a broader spectrum of colours and effects, including holographic options. Try this on gift boxes for special events and giveaways!

Cold Foil

If hot foil exists, so does cold foiling but with a few differences! This type of embellishment can be applied to spot on the right position without a registration issue. Additionally, cold foil is great to create fine lines as thin as 0.02mm and produce a more intricate design.

Emboss

Sometimes it’s all about the texture! Embossing involves raising specific elements on the base paper stock as high as the paper fibres allow. You may combine with hot stamping to produce an unparalleled high-end finish and texture!

Deboss

Debossing involves pressing a design or text into the surface of the material, creating a recessed effect. The exceptional stretch properties of the paper enable deep embossing, surpassing three times the paper’s thickness. This capability facilitates the creation of multi-layered emboss and deboss shapes, resulting in striking 3D effects that catch the eye.

Foil Stamping & Emboss

This one is a good combination you can consider for bags and boxes! Embossing involves the creation of a raised impression on the surface of a material and when added with foil stamping, creates a striking finish! During the process, a metal plate is pressed into the material utilising both heat and pressure. As a result, the design or text is raised above the material’s surface, adding a tactile and visually distinctive element.

Foil Stamping with 3D Effect

Foil stamping with a 3D effect is a printing technique that combines the luxurious shine of foil with the illusion of depth through an emboss, creating a visually stunning and tactile design. Beginning with intricate artwork preparation and custom die creation, the chosen foil is stamped onto the surface with heat and pressure, emphasising specific areas to achieve a shiny, metallic finish.

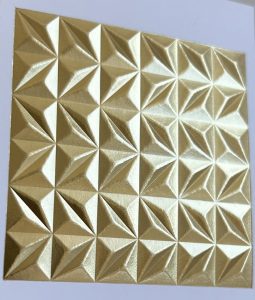

Metallic Ink Printing & Emboss

Don’t miss this out if you’re looking for a metallic finish! This embellishment incorporates metallic particles into the ink, typically silver or gold. These particles reflect light, creating a shimmering effect reminiscent of metal. Unlike standard CMYK colours, metallic ink is a spot colour, applied with a single printing plate. It finds application in various areas such as business cards, game packaging, screens, and instruction booklets, adding elegance and flair!

Contrasting metallic ink with an embossed design provides a layer of sheen and brightness, providing a look of premium and lux.

Spot UV

Lastly, there’s spot UV! It is a sophisticated printing technique that adds a glossy, protective layer to specific areas of printed materials, enhancing design and durability. Unlike full UV coating, which covers the entire surface, spot UV selectively targets areas for added shine and emphasis.

Range of Label Embellishments

Packaging labels are essential components of product packaging. They serve as promotional tools, attracting attention and influencing purchasing behaviour. Make sure you can get them printed clearly, choosing from various embellishments available.

Bespoke Die Cutting

First one, there’s bespoke die cutting. It involves the creation of custom shapes by cutting paper or other materials using specialised dies. These shapes can be utilised for various purposes such as packaging boxes, invitations, business cards, and more!

Screen Printing

Secondly, there’s screen printing for labels! It involves the application of ink through a mesh screen onto various packaging materials, such as paper, cardboard, plastic, or metal. This technique allows for the transfer of intricate designs, logos, or graphics onto packaging surfaces with precision and vibrancy. It is a common technique for embellishing small or moderate volumes of packaging, labels, graphics, garments, and other products!

High Build Raised Printing

Next we have high build raised printing that adds a layer of texture! This is achieved by applying a thick layer of ink or coating to packaging surfaces, creating a raised or three-dimensional effect that enhances design elements, provides protection, and offers a tactile experience for consumers.

Photo credit: resource label

Rough Varnish

This specialised varnish creates a subtle, textured finish on packaging surfaces. Strategically applied to specific areas, rough varnish creates visual contrast with smoother, glossy sections, enhancing the design’s depth and interest. Beyond aesthetics, rough varnish provides protection against scratches, scuffs, and moisture damage, ensuring the durability of the packaging. They’re great for beverages and wine bottles for that much needed texture!

Printable Varnish & Lamination

This embellishment allows the over print or add dates and batch number onto the labels which would allow your product to communicate delicate information clearly to consumers. Varnish is a liquid coating that protects the ink and label, available in glossy or matte finishes, and is cost-effective but less durable while lamination is a thin plastic film bonded to the label surface, providing superior moisture and scuff resistance, and is ideal for labels exposed to harsh conditions!

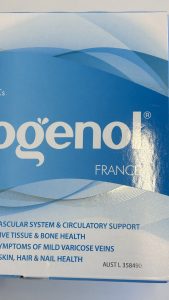

Metallic ink, Hot Foiling, Cold Foiling & Emboss

Similar to the techniques applied on paper bags and boxes, these packaging embellishments are popular for labels as well! Here’s an example of a packaging utilising the metallic ink technique on the label.

Photo credit: resource label

Wrapping It Up

When making strategic embellishment choices, it’s important to ensure that each embellishment serves a purpose. Are you enhancing perceived value, reinforcing brand messaging, or letting your design come to life? Each choice should contribute to the overall aesthetic and messaging of your brand. Partner with Myerton Packaging to discuss your custom packaging plans and explore our wide-array of embellishments to suit your needs!